A sewing machine serves as a fundamental tool for seaming fabric pieces together, hemming edges for a polished finish, quilting for added texture and design, and embellishing or decorating fabric items with various decorative techniques.

Seaming:

Using a sewing machine to stitch pieces of fabric together like a puzzle, creating clothes and other fun things by joining them with strong stitches.

Hemming:

Making the edges of clothes look neat and tidy by sewing a special stitch to prevent fraying, just like giving clothes a tidy haircut along the edges.

Quilting:

Making cozy blankets by sewing lots of layers together with special stitches, creating colorful patterns and keeping you warm and snuggly.

Embellishment:

Making clothes and crafts extra pretty by adding decorations like flowers, buttons, or colorful stitches, turning ordinary things into special and unique creations.

Decorative Techniques: Using a sewing machine to make fabric look fancy and unique, adding special designs and stitches to make it as cool and creative as possible.

Blind stitch machine

When a garment needs stitches that should be hidden, a blind stitch machine is the perfect choice. This machine swiftly and precisely creates invisible hems or bonds on garments, achieving a seamless look that’s challenging to achieve otherwise. While its functionality is limited to these tasks, it proves invaluable in crafting garments that demand a smooth and illusionary appearance when worn.

The blind stitch is also known as the invisible stitch or slip stitch

Example Usage:

A blind stitch machine is often used in sewing elegant evening gowns, where concealing seams is crucial to maintain a polished and flawless look. It’s also handy for creating seamless hems on delicate fabrics, ensuring a refined finish on garments like flowy skirts and dresses.

Mechanical Sewing Machine

A Mechanical Sewing Machine is a traditional type of sewing machine that is manually operated and designed for a wide range of sewing applications. It is powered by a rotary wheel which is controlled by the user via a foot pedal. The user has to manually adjust the tension, stitch length, and stitch style according to their sewing needs.

These machines are known for their durability and longevity, often being passed down from generation to generation. They are ideal for basic sewing tasks such as hemming, mending, crafting, and simple garment making. Despite their lack of digital features, mechanical sewing machines offer precision and control that can be appreciated by both beginners and experienced sewers alike.

Mechanical sewing machines are typically more affordable than their computerized counterparts, making them a popular choice for those on a budget or those just starting out in sewing. They are also easier to maintain due to their simple construction. However, they may not offer as many stitch options or features as computerized or electronic sewing machines. Despite this, a mechanical sewing machine is a reliable and practical tool for anyone interested in sewing.

Electronic Sewing Machine

An Electronic Sewing Machine is a modern type of sewing machine that uses electricity to automate many of the tasks traditionally done manually on a mechanical sewing machine.

These machines come with a variety of built-in stitches, which can be easily selected with the push of a button. The machine then automatically sets the optimal stitch length and width, although these settings can often be overridden for more control.

Electronic sewing machines also typically include features such as automatic needle threading, automatic buttonhole sewing, and built-in thread cutters, which can greatly speed up sewing tasks and make the process more efficient.

Some advanced models may also include features such as embroidery capabilities, programmable stitch sequences, and even touch screens for easy navigation.

While electronic sewing machines are generally more expensive than mechanical models, they offer a greater range of capabilities and ease of use, making them a popular choice for serious hobbyists and professionals. However, they may require more maintenance and repairs due to their complex electronic components.

Single Needle Lock Stitch Machine

A Single Needle Lock Stitch Machine is a type of sewing machine that is widely used in the garment industry. It is designed to create a lock stitch, which is the most common type of stitch used in sewing.

The machine uses a single needle and thread to create a stitch on the top side of the fabric, while a bobbin thread is used to create a loop on the underside, locking the stitch in place. This results in a secure and durable stitch that is suitable for a wide range of fabrics and applications.

Single needle lock stitch machines are known for their precision and consistency, making them ideal for detailed work and high-quality garment construction. They are typically equipped with features such as adjustable stitch length, reverse stitching capability, and a built-in thread cutter.

While they may not offer the versatility of multi-needle machines or the automation of computerized machines, single needle lock stitch machines are valued for their reliability and ease of use. They are a staple in both home sewing rooms and professional garment factories.

Computerized Sewing Machine

A Computerized Sewing Machine is a highly advanced type of sewing machine that uses computer technology to automate and enhance the sewing process.

These machines come equipped with a microprocessor, which allows for a wide range of automated features. This includes automatic needle threading, automatic tension control, automatic thread cutting, and automatic buttonhole sewing.

One of the key features of a computerized sewing machine is its ability to create a vast array of stitch patterns. These machines often come pre-programmed with hundreds, or even thousands, of different stitch designs, which can be easily selected via a touch screen or push-button controls. Some models even allow users to download or create their own custom stitch patterns.

In addition to basic sewing tasks, many computerized sewing machines also offer advanced capabilities such as embroidery, monogramming, and quilting. Some models may also include features like programmable stitch sequences, adjustable sewing speed, and mirror imaging of stitches.

While computerized sewing machines are generally more expensive than mechanical or electronic models, they offer unparalleled versatility and convenience, making them a popular choice for advanced sewers and professionals. However, they may require more maintenance and can be more complex to use, particularly for beginners.

Embroidery Sewing Machine

The Embroidery Sewing Machine is a remarkable piece of technology that brings together the art of embroidery and the efficiency of a sewing machine. It’s designed to create intricate and detailed embroidered patterns on fabric, enhancing the beauty of your sewing projects.

This machine offers a wide range of pre-programmed embroidery designs, but also allows you to upload your own designs, giving you the freedom to personalize your projects. With its user-friendly interface, it’s easy to select and edit designs, change thread colors, and adjust stitch density.

The Embroidery Sewing Machine also features an automatic needle threader, saving you time and effort. Its large embroidery area provides ample space for larger designs and lettering, making it ideal for home decor items, clothing, and more.

Whether you’re a seasoned professional or a beginner, the Embroidery Sewing Machine is a versatile tool that can help bring your creative visions to life. It’s not just a sewing machine, it’s a gateway to endless creative possibilities.

Lockstitch Sewing Machine

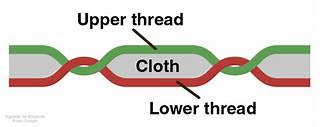

A Lockstitch Sewing Machine is a commonly used type of sewing machine in the textile industry, known for creating secure and durable stitches. It is named so because it creates a stitch where two threads – the top thread and the bottom thread – are locked together in the fabric.

The machine works by using two threads: one from the needle and the other from the bobbin. The needle goes through the fabric and loops around the bobbin thread, creating a lockstitch. This type of stitch is strong and durable, making it ideal for sewing clothing, bags, and other textile products.

One of the benefits of using a lockstitch sewing machine is the ability to adjust the stitch length and width. This feature allows you to customize your sewing project to meet your needs. Additionally, the lockstitch sewing machine is reliable and requires minimal maintenance. With proper care and maintenance, this machine can last for years, making it a worthwhile investment for any sewing enthusiast.

The most prominent part of a lockstitch sewing machine is the needle, which passes through the fabric to create the stitch. The needle is held in place by a needle bar, which moves up and down to create the stitch formation. Another important component is the bobbin, which holds the thread that’s used to create the bottom portion of the stitch. The bobbin is located underneath the fabric and is held in place by a bobbin case.

Lockstitch sewing machines are versatile and can be used to sew a variety of fabrics, from light-weight cotton to heavy-duty leather. They are also popular in home sewing and crafting, as they are easy to use and produce high-quality stitches.

Overlock sewing machine

An Overlock sewing machine is a specialized type of sewing machine that uses multiple thread cones and two needles. Unlike a lockstitch sewing machine, it uses loopers fed by multiple thread cones rather than a bobbin. These loopers create thread loops that pass from the needle thread to the edges of the fabric, containing the edges of the fabric within the seam.

This machine is used to lock the edges of fabric or sew two pieces together. Depending on the type of overlock machine, it can be used for decorative hemming, flatlock stitching, edge rolling, and elastic sewing. Some of these machines come with built-in blades that trim off excess fabric along the edges to prevent fraying.

Overlock machines are versatile and can be used to sew a variety of items, from sportswear and draperies to placemats and napkins. They can handle all kinds of materials, including denim and woven fabric, and can sew up to 1300 stitches per minute.

In terms of pricing, the cost of an Overlock sewing machine can vary widely depending on the brand and features. For instance, the price can range from around ₹3,000 for a basic model to over ₹50,000 for a high-end model with advanced features.

Bar Tack Sewing Machine

A Bar Tack Sewing Machine is a specialized type of sewing machine designed to increase the strength of a small length of fabric by repeatedly sewing over it. This machine is commonly used for reinforcing areas that will encounter stress or additional wear, such as belt loops and pocket openings.

The machine operates in a simple automatic cycle, producing stitches in a specific order1. Initially, it creates tack stitches over a small length (1-2 cm), and then sews covering stitches over and at right angles to the first stitches. The number of tacking stitches and the number of covering stitches can be varied.

The Bar Tack Sewing Machine is a lockstitch machine that produces a very high-density stitch in a short length, thereby increasing the strength of that particular area. It can be used with a variety of needle sizes and can achieve a sewing speed of 3000-3600 stitches per minute.

In India, various models of Bar Tack Sewing Machines are available from different brands like Jack, Juki, and Texking, with prices ranging from ₹1,25,000 to ₹2,50,000. These machines are typically used for industrial purposes.

Flat Seam Machine

A Flat Seam Machine is a specialized type of sewing machine used to create flat seams on knit garments or textile products. It’s often used to bind cut edges and create a final product with a seam that’s flat on both sides.

For instance, the Yamato FD-62SD-LF is a Flatseamer designed for stretch materials that reduces defects and achieves extra stretch, outstanding appearance, comfort & functionality. It also has a series of optional devices like the RF device which is an auxiliary rear feeding device for feed-off-the-arm type flatseamers.

Another example is the Pegasus FS-713 Flat Seamer Sewing Machine. It is used for joining the side of sportswear, joining the side and crotch of light wet suits, and for medium to heavy weight fabrics. This machine is capable of producing uniform stitches on difficult-to-sew fabrics, increasing the quality of the finished products.

These machines are known for their durability, stability, and the neat, beautiful seaming they produce. They are essential tools in the textile industry, particularly for the production of garments such as underwear, T-shirts, and wetsuits.

Double Needle Lock Stitch Machine

The Double Needle Lock Stitch Machine operates on the same principle as a single needle lock stitch machine, but with two needles and two bobbins, resulting in two parallel rows of lockstitch. This technique is also popularly known as double needle sewing.

This machine is used to sew box pockets in jackets, light jeans, pajamas, and many more. It features a bottom feed, needle feed, and alternating feet, along with an electromagnetic thread trimmer, electropneumatic seam backtacking, and a sewing foot lift. The needle bar, walking foot bar, and presser foot bar are DLC coated.

The machine is suitable for medium-weight applications and is particularly useful for handbags, suitcases, sofas, gloves, camping materials, shoes, auto internal decorations, and leather materials. It can handle all types of sewing of light and heavy weight fabric’s garments, including belts or loops of trousers.

The machine’s specifications include a stitch per minute (S.P.M) range of 4000-5000, needle sizes ranging from 9 to 21, and a stitch class of 3001. The machine uses two needles and has a flat-bed design. The thread source includes a needle thread from a cone package and under threads from the bobbin case of the machine.

One of the challenges of using this machine is the shortage of bobbin thread. The capacity of the bobbin storage is low and needs to be rewound after a certain time of sewing.

Single Needle Chain Stitch Machine

The Single Needle Chain Stitch Machine is a sewing machine designed to sew stitches in a short amount of time. It operates on the principle of a chain stitch, which is a series of looped stitches that form a chain-like pattern.

This machine works by driving a needle through the fabric, pulling the thread along with it. The single needle chain stitch goes in and out of the fabric, creating a continuous chain of stitches. This process is similar to sewing by hand, but the machine does all the hard work, leading to more accurate results.

The Single Needle Chain Stitch Machine is used for various sewing applications. It’s particularly useful for creating decorative topstitching and edgestitching on garments. It can also be used for sewing labels onto items, attaching trims, and other similar tasks.

One of the advantages of this machine is its speed and efficiency. It can sew stitches much faster than manual sewing, saving a significant amount of time. However, like all machines, it requires regular maintenance to ensure it continues to operate smoothly.

The specifications of the machine can vary depending on the model, but typically it has a high sewing speed, often up to 2000-3000 stitches per minute. The needle bar stroke is usually around 30.7mm, and it can handle a variety of thread types and fabric thicknesses.